while in the professional flooring sector, vinyl flooring has very long been a most popular Alternative because of its sturdiness, style and design flexibility, and cost-efficiency. However, as awareness surrounding material wellness and environmental basic safety proceeds to develop, brands and suppliers while in the vinyl flooring wholesale business ought to confront a essential question: Is your vinyl flooring actually Protected?materials security is currently The most scrutinized aspects of flooring goods, specifically in industrial environments the place use is intensive, and in which shoppers count on not only efficiency but additionally lengthy-expression well being and environmental assurance. From chemical emissions to provide chain transparency, each and every ingredient during the manufacturing and lifecycle of vinyl flooring is beneath the Highlight.This comprehensive tutorial breaks down The crucial element Proportions of vinyl flooring basic safety and gives actionable insights for virtually any business vinyl flooring supplier aiming to foreseeable future-proof their brand name, defend finish-buyers, and keep in advance of rules.

Table of contents:

1. Chemical Emissions: A twin-stage issue

2. Raw Material choice: Purity Equals protection

3. production Hygiene: Clean procedures for Clean items

four. Certifications and Regulatory Compliance

five. susceptible Populations: layout for protection

six. extensive-Term Durability and Safety

7. clear Supply Chains: No strategies, No Surprises

one. Chemical Emissions: A twin-section problem

shorter-phrase Emissions just after Installation

Upon set up, several vinyl flooring goods emit risky natural compounds (VOCs), for instance formaldehyde, toluene, and xylene. These substances contribute to indoor air air pollution and so are recognised to bring about respiratory irritation, complications, and also lengthy-term health problems in delicate persons.

In professional Areas like offices, retail suppliers, and healthcare services, indoor air excellent plays a pivotal purpose in person convenience and safety. Original off-gassing can undermine the perceived high quality of your product and raise worries among the facility managers and clients.

Mitigation Strategy: inspire the usage of pre-treatment method procedures like significant-temperature curing or pre-installation airing out, which accelerates the release of VOCs prior to the flooring is installed. This helps provide a product that is definitely safer from working day one.

lengthy-expression Chemical Leaching

Even after the First off-gassing subsides, sure substances can go on to leach with time. Notably, plasticizers for instance DEHP (a type of phthalate) and large metals like direct and cadmium can migrate in the flooring to the air or dust, notably in high-warmth or humid environments.

as an example, underfloor heating programs, which can be more and more common in professional properties, can intensify these emissions, bringing about probable well being hazards around extended publicity.

Mitigation technique: spouse with makers who've phased out harmful substances in favor of safer solutions, like calcium-zinc stabilizers and non-phthalate plasticizers. These formulations drastically lessen extended-time period chemical exposure.

two. Raw product assortment: Purity Equals Safety

PVC Base Resin high-quality

the inspiration of vinyl flooring is its polyvinyl chloride (PVC) layer. If this foundation includes residual vinyl chloride monomer (VCM) or is produced from reduced-excellent recycled PVC, it could possibly harbor impurities and not known contaminants.

Resolution: Commercial buyers ought to desire comprehensive transparency around the origin and grade of PVC employed. Virgin, meals-grade, or healthcare-quality PVC resins make sure a clean starting point and lessen risks connected to recycled or contaminated raw components.

Protected Additives and Stabilizers

Vinyl flooring items consist of various additives—plasticizers, stabilizers, flame retardants, UV absorbers—that add to functionality. But several of such additives may also be recognised to include substances of issue, for example BPA or halogenated flame retardants.

Answer: function with makers who prioritize bio-centered plasticizers, for example soybean oil derivatives, and non-halogenated flame retardants like magnesium hydroxide or aluminum hydroxide. These materials preserve fire resistance and flexibility while doing away with toxicity concerns.

three. Manufacturing Hygiene: clear procedures for thoroughly clean merchandise

Residual Solvents and Byproducts

Vinyl flooring producing usually includes solvents and chemical procedures that will leave powering residues Otherwise appropriately managed. Substances like acetone, methyl ethyl ketone, or unreacted monomers can be trapped in the ultimate item.

Alternative: associate only with suppliers who use shut-loop generation programs with solvent Restoration premiums higher than 95%. These programs lower waste, strengthen air high-quality, and minimize leftover chemical residues inside the flooring.

Cross-Contamination in Shared amenities

Facilities that develop several products lines may perhaps pose a danger of cross-contamination, especially if poisonous substances (e.g., asbestos-centered items) are handled nearby.

Remedy: Insist on committed output lines or isolated workshops for vinyl flooring items. highly regarded suppliers should also present third-get together certification stories validating the cleanliness and purity of their amenities.

4. Certifications and Regulatory Compliance

Global Environmental Certifications

Gaining certifications like GREENGUARD Gold or Blue Angel is a powerful way for suppliers to differentiate their products and solutions. These certifications validate compliance with rigorous emission thresholds and environmental safety requirements in the course of an item’s lifecycle.

For GREENGUARD Gold, flooring need to meet really small VOC emission restrictions, which makes it appropriate for use in educational institutions, hospitals, and Business office environments. Blue Angel goes even more by analyzing useful resource effectiveness, product recyclability, and stop-of-everyday living impression.

Regional authorized specifications

each professional vinyl flooring supplier will have to stay up to date with worldwide and regional restrictions. the eu Union’s REACH legislation, for example, maintains a listing of Substances of quite High issue (SVHC), which now incorporates in excess of two hundred compounds. In China, expectations like HJ 2502-2010 element specifications for eco-welcoming flooring.

Alternative: Regularly audit products and solutions from get to, RoHS, and various relevant environmental requirements. Should your product or service is exported globally, compliance need to extend beyond the minimum amount domestic prerequisite.

practical Testing eventualities

lots of flooring products pass laboratory emissions tests below great situations, but fail in authentic-globe situations like high-humidity or flooring-heated environments.

Resolution: Request emissions screening under simulated use circumstances—e.g., 28°C temperature with 65% relative humidity—to obtain a sensible emissions profile. Use this information to guideline potential buyers and bolster transparency.

5. susceptible Populations: style and design for Safety

Child and Maternal wellness

Phthalates and related chemical compounds are known endocrine disruptors that will have an impact on hormone advancement in fetuses and children. In Areas like daycares, hospitals, and educational facilities, flooring has to be Safe and sound for essentially the most vulnerable populations.

Solution: Choose flooring that complies with U.S. CPSC (customer merchandise basic safety Commission) benchmarks for kids’s products and solutions. solutions needs to be no cost from phthalates together with other suspected endocrine disruptors.

Allergen-Free overall performance

steel ions like nickel and cobalt, often current in ground coatings, can result in skin reactions or allergic reactions. Furthermore, antimicrobial brokers such as triclosan can cause sensitivities.

Answer: hunt for flooring Licensed as hypoallergenic and tested by independent dermatological labs (e.g., Dermatest). Product packaging or requirements must Evidently converse allergy-friendly standing.

6. extensive-time period longevity and protection

Environmental Resistance

As components age, their chemical steadiness can change—specifically in harsh environments. In sizzling and humid business Areas, some flooring solutions may perhaps start to emit extra VOCs with time.

Remedy: Insist on multi-environment testing that simulates many years of use less than distinct situations, such as 40°C and ninety% humidity. Use these results to show the long-time period steadiness and protection of your respective offerings.

Resistance to Abrasion and problems

with time, have on and tear to the surface layer could expose fundamental products. If those further layers are certainly not as chemically steady, This tends to boost emissions or expose harmful substances.

Alternative: boost monolithic vinyl structures in lieu of multi-layer laminates. A fully compact, non-layered materials structure maintains integrity greater underneath mechanical stress.

7. Transparent source Chains: No techniques, No Surprises

Raw content Traceability

a growing selection of business purchasers commercial vinyl flooring supplier are demanding entire traceability For each and every element with the merchandise they invest in. This contains plasticizers, PVC resin, flame retardants, and stabilizers.

Resolution: be sure that your upstream suppliers hold certifications for instance ISO 9001 and provide documentation on raw material origin. Full supply chain mapping is no more optional—it’s the market normal.

Packaging Safety

Even packaging elements make any difference. Some vinyl flooring is delivered working with recycled plastics that may leach harmful substances in the product in the course of storage or transport.

Answer: Choose pure polyethylene (PE) packaging and stay away from using non-Licensed recycled elements. Make packaging safety a visual aspect of your respective top quality guarantee.

Strategic basic safety Actions for business Vinyl Flooring Suppliers

to take care of leadership and achieve rely on inside the vinyl flooring wholesale market, Here i will discuss various key actions each supplier ought to just take:

Define and Publish a Safety Threshold record

contain formaldehyde (≤0.05 mg/m³), phthalates (≤0.one%), together with other chemical restrictions. Make this list visible on your internet site or in item documentation.

check and Adapt to world rules

Stay ahead of future improvements in laws like arrive at, CLP, or perhaps the U.S. TSCA. Regulatory readiness provides you with a aggressive edge.

employ wise Transparency Tools

incorporate QR codes on packaging or products webpages that website link to VOC emission graphs, certification scans, and third-get together lab reports. This visual info builds purchaser confidence.

In the trendy commercial natural environment, flooring need to do greater than search very good or last lengthy. It have to be Risk-free—right away and with time—for everybody who will come into contact with it.product safety is no longer an insert-on; it’s a Main element. For suppliers who prioritize chemical transparency, liable manufacturing, and long-expression wellness, the payoff is obvious: brand believability, shopper loyalty, and regulatory safety.manufacturers like GREEN POINT have taken the lead by utilizing these methods and giving business vinyl flooring remedies that mirror the highest safety and environmental benchmarks. For every business vinyl flooring supplier aiming to thrive in another ten years, next this product is not just proposed—it’s vital.

Emilio Estevez Then & Now!

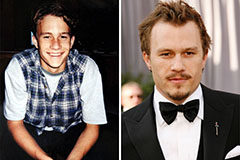

Emilio Estevez Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now!